【温馨提示】 购买原稿文件请充值后自助下载。

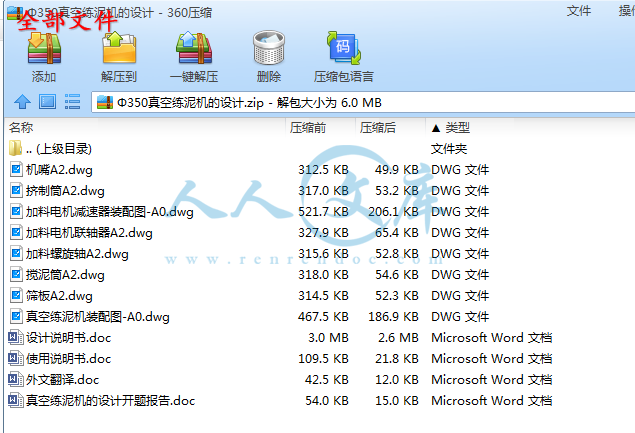

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

随着机械制造技术的进步,人们对练泥技术的要求也越来越高。常规型单轴式真空练泥机制品的质量有所提高。但由于常规型单轴式真空练泥机存在许多的不足,如今发展多轴式真空练泥机已成为时代发展的潮流。

真空练泥是为了将用于滚压的泥料搅拌均匀,让水分分布均匀,抽出泥料中包裹的空气,让压制的产品更加匀实。本文在查阅了国内外关于真空练泥技术的基础上,针对设计任务要求,进行了真空练泥机的设计。首先,进行了总体方案的设计、分析和确定。本课题设计的练泥机采用的是双轴真空练泥机。其次,以真空练泥机上加料系统、挤制系统和真空系统为主线,对练泥机展开了详细的设计。

总体上看,所设计的真空练泥机。结构比较简单,有较好的进料特性、输送特性、良好的抽真空性能,而且,生产效率也较高。

关键词:练泥技术 双轴真空练泥机 加料系统 挤制系统 真空系统

ABSTRACT

With advances in technology, machinery manufacturing, people pug technical requirements are also increasing. Conventional vacuum practicing uniaxial product quality has improved mud mechanism. However, since the conventional single-axis vacuum pug mill there are many shortcomings, and now the development of multi-axis vacuum pug mill has become the trend of the times.

Vacuum pug is to be used for rolling the mud Stir and let the water distribution, air parcels out of mud compound, so that the product is more uniform pressing reality. Based on a domestic and international basis with respect to the vacuum pug technology, for the design task requirements, vacuum pug mill design. First, the design, analysis, and determine the overall program. This topic clay extruder design uses a dual-axis vacuum pug mill. Secondly, the vacuum pug mill feeding system, extrusion and vacuum systems as the main line of pug mill launched a detailed design.

Overall, the design of the vacuum pug mill. Structure is relatively simple, there is a good feeding characteristics, transport properties, good vacuum performance, and production efficiency is higher.

KEYWORDS: pug technology dual-axis vacuum pug mill feeding system extrusion system vacuum system

目 录

1 绪论 5

1.1 真空练泥机的概述 5

1.2 真空练泥机的工作原理 5

1.3 真空练泥机的主要结构 8

1.4 真空练泥机国内外研究现状 9

1.5 本课题设计的目的及任务 10

2 真空练泥机整体方案的设计 11

2.1 真空练泥机技术参数的确定 11

2.2 真空练泥机整体结构方案的确定 11

3 传动系统的设计与计算 14

3.1 加料传动系统的设计 14

3.2 挤制传动系统的设计 20

3.3 螺旋推进器的设计 26

3.4 机头、机嘴的设计 27

3.5 筛板的设计 28

4 练泥机真空系统的设计 29

4.1 真空泵的设计 29

4.2 真空室的设计 30

4.3 滤气器的设计 30

5 结论 32

6 经济分析报告 33

致 谢 35

参 考 文 献 36

绪论

1.1 真空练泥机的概述

为了消除压滤机泥饼的各组分分布不均匀和含有气泡等缺陷,一般是用真空练泥机对泥料进行加工,泥料经真空练泥机加工后,各组分的分布趋于均匀,结构比较致密,泥料的可塑性和干燥强度都有提高。

真空练泥机可安装如下分类方式进行分类:

1、按用途真空练泥机分为:

1)普通练泥机:对泥料混合、搅拌、运送;

2)真空练泥机:对泥料进行制备和脱气;

3)真空挤泥机:对泥料进行制备并挤压成型;

4)真空喂泥机:为自动成型生产线定量喂泥。

2、按练泥级数、螺旋轴多少和布置形式分为:

1)练泥机级数有单级的、双级的,每级内的螺旋轴有单轴、双轴的。

2)螺旋轴的布置有水平式和垂直式。当练泥机挤出螺旋轴线是水平布置的,称卧式练泥机;当挤出螺旋轴线是垂直布置的,称立式练泥机

川公网安备: 51019002004831号

川公网安备: 51019002004831号